Our continuous investments in research and development led us to be one of the first foundry in Italy that can certify the mechanical characteristic of cast alloys.

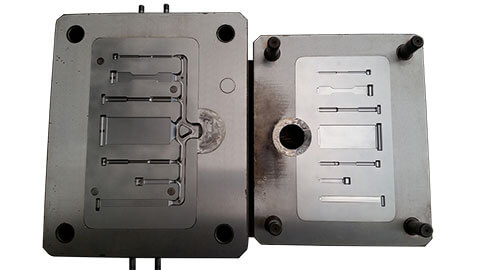

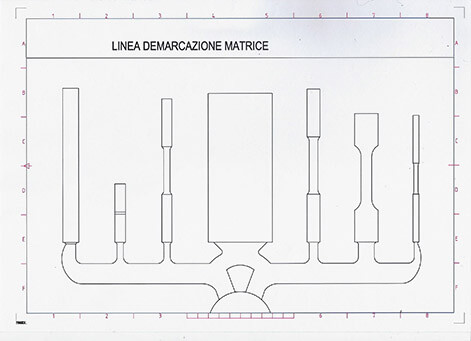

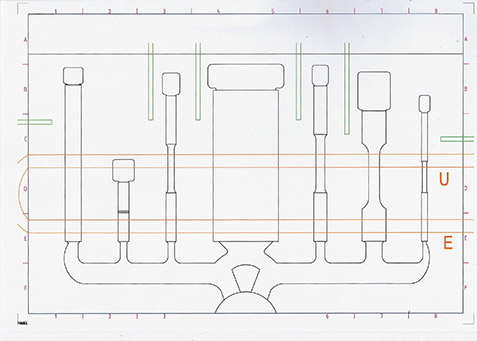

Using an internal projected mould, we created a casting with seven test pieces. Each one respects the fixed size of the ASTM standard which regulate the test of traction of circular and flat cross-section, resilience, corrosion and flowability.

We did a die-casting cycle for each alloy, always on the same machine, configurated with the same guidelines. After the selection of the pieces, we perform the test described above and we got certified results from an accredited laboratory.

This project intends to be helpful for our customers, who are going to plan their molten products and for our staff as an important technical background.

To achieve a higher repeatability of our generated data, our mould is equipped with thermoregulation circuit, which is studied in such a way that every track would be involved by the diathermic fluid. The operating temperature was kept the same for the whole process. The dies are built with W300 steel, the most common steel used in our die-casting moulds.